Table of Contents

Piezoelectric Ceramic & Film

Intro: Piezoelectricity and the Piezoelectric Effect

The word is derived from the Greek word “piezein”, which means to squeeze or press. Piezoelectricity is the ability of some materials to generate an electric potential in response to applied mechanical stress. The piezoelectric effect is caused by the appearance of electric polarization in a material that strains under stress. Piezoelectricity is therefore a reversible effect: if a voltage is applied to a piezoelectric device, it will strain. The electrical response to mechanical stimulation is called the direct piezoelectric effect and the mechanical response to electrical simulation is called the converse piezoelectric effect.

The discovery of the piezoelectric effect dates back to the 1880s and emerged out of a series of measurements of surface charges appearing on specially prepared crystals (tourmaline, quartz, topaz, cane sugar, etc) In other words, the search for a connection between macroscopic piezoelectric phenomena and crystallographic structure lead to the discovery of this effect, which was considered quite a “discovery,” and was quickly dubbed as “piezoelectricity” in order to distinguish it from other areas such as “contact electricity” (friction generated static electricity), “pyroelectricity” (electricity generated from crystals by heating), and piezoresistivity (change of resistance under pressure/deformation).

Devices and Material

Piezoelectric devices are pervasive in our high-tech world. Quartz crystal time keeping devices, flint-free electric butane lighters, and “intelligent” shock absorbing sports equipment all make use of piezoelectric materials. Piezoelectric materials are also used as actuators in speakers, motors, and buzzers.

Many materials, both natural and man-made, exhibit piezoelectricity. Many biological tissues such as tendon, intestine, silk, bone, and wood exhibit piezoelectricity. Some naturally-occurring crystals include: quartz, cane sugar, Rochelle salt, topaz, and tourmaline-group minerals. Lead zirconate titanate or PZT (a man-made ceramic) is the most common piezoelectric ceramic in use today. Polymers such as Polyvinylidene fluoride (PVDF) exhibit piezoelectricity several times greater than quartz.

Piezoelectric elements are commonly modeled electrically as a parallel capacitance, leakage resistance, and pressure dependant current source (or under source transformation: a series resistance, capacitance, and voltage source).

Sensor/Material characteristics

For sensing technology , the material is available mainly in two forms, ceramic crystals (quartz, PZT) and polyvinylidene fluoride (PVDF) film, though many materials exhibit the piezoelectric effect to a much lesser degree. In comparison with crystals, polyvinylidene fluoride (PVDF) piezo films offer wider dynamic and frequency range, higher sensitivity and are mechanically tougher.

Pros:

- good span, passive, accurate, good resolution, linear, cheap, easy to find and work with

Cons:

- Hysteresis (the lagging of an effect behind its cause): All piezoelectric materials exhibit a mechanical hysteresis as the strain does not follow the same track upon charging and discharging. The mechanical hysteresis (in voltage) depends on the type of ceramics and can vary from 4% to 20%. (Note: Hysteresis is expressed as the maximum strain divided by the maximum difference between the two tracks.)

- Creep (effecting error and precision): Piezoelectric materials exhibit a creep effect i.e. the material continues to expand for some time upon charging. Correspondingly the material does not immediately return to the initial strain level upon discharging. (Typical values range from 1% to 20% with time constant between 10 and 100 seconds.)

- It should be noted that piezoelectric materials have strong pyroelectric (temperature dependant) properties. These properties can either be harnessed to sense temperature, or the unwanted effect must be taken into account or reduced when designing with these materials.

Sensors and Elements

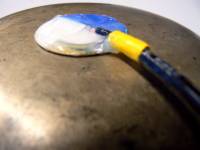

Piezo sensors are used to convert mechanical movements, such as force, vibration, acceleration or pressure, into electric signals. Piezoelectric elements are widely used in a variety of sensors such as accelerometers, contact mics, and ultrasound transducers. Piezoelectric sensors can be used as force-sensitive switches, threshold detectors, analog pressure sensors, and acoustic vibration pickup.

Piezoelectric ceramic elements are also found in watches, alarm clocks, old portable video games, and many other commercial products which contain sound generating devices. Piezo-buzzers typically operate at their resonant frequency with various construction options. Since in many cases piezo sensors are simply reversed buzzers and actuators, these sensors exhibit a resonant frequency that they are more sensitive to. These inexpensive transducers can be salvaged from old products or obtained from the usual sources (i.e. digikey, etc.) with specific electrical properties (operating voltage range, sensitivity, capacitance, resonant frequency, etc.) for optimal operation.

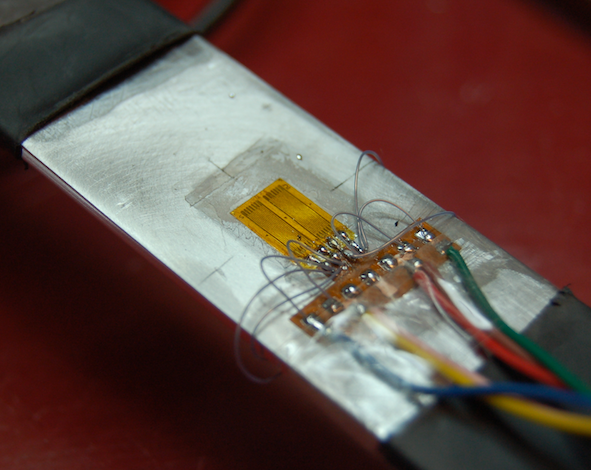

Mesurement Specialties Inc. make a wide range of piezo film (and many other disparate) devices. Their piezo sensors can be used to sense vibration, pressure, shock, and flexion. The devices come in pre-cut sensor elements, coaxial cable, and piezo film sheets. For details on implementing these devices in sensors and actuators refer to their technical manual. Many of these sensors are available through digikey.

Interface Design and Conditioning

Always make sure to properly and securely place, mount, shield and ground the piezo to avoid false-vibrations/distortion, electromagnetic interference and electrical or acoustical cross-talk.

Care must be taken in the design of piezoelectric sensing circuitry. Application-specific load resistance matching and buffering are a must. Filtering, averaging, and differential sensing are the common approaches to reduce band-specific noise, random noise on periodic signals, and common-mode noise respectively. Other design problems include electromagnetic interference and electrical or acoustical cross-talk.

When used as an (audio-rate) acoustic-vibration pickup, standard dsp and sound analysis techniques are useful for signal extraction. Also envelope following, smoothing and filtering are popular techniques.

Sample parts and Resourses

| Measurement Specialties Inc. 0-1002794-0 | |

|---|---|

| Sources | Digikey CAN$ 1.44 |

| Description | 0.005“(125µm) polyester layer laminated to a 28µm piezo film element. |

| Datasheet | LDTO Vibration Sensor.pdf |

| Resources | |

| Notes | |

| Variants | MSI 0-1005447-1 piezo film with mass. |

| Murata 7BB-18R2-11 | |

|---|---|

| Sources | Electronic-Goldmine 2/$1.00 |

| Description | Tiny 3/4” diameter Piezo disk element. |

| Datasheet | |

| Resources | |

| Notes | |

| Variants | |

| Projects Unlimited AB1070B | |

|---|---|

| Sources | Mouser Electronics CAN$ 0.83 |

| Description | 7.4mm Piezoelectric Bender 7000HZ 1000 OHM |

| Datasheet | Mouser 665-AB1070B |

| Resources | |

| Notes | |

| Variants | |

Media

References

- Miranda & Wanderley, “New Digital Musical Instruments”