Differences

This shows you the differences between two versions of the page.

| Next revision | Previous revision | ||

| sensors:force-sensitive_resistor [2018/11/01 18:55] – external edit 127.0.0.1 | sensors:force-sensitive_resistor [2022/03/20 20:13] (current) – [Devices] brady.boettcher | ||

|---|---|---|---|

| Line 3: | Line 3: | ||

| ===== Summary | ===== Summary | ||

| ==== Introduction | ==== Introduction | ||

| - | A **force-sensitive resistor** (alternatively called a **force-sensing resistor** or simply an **FSR**) has a variable resistance as a function of applied pressure. | + | A **force-sensitive resistor** (alternatively called a **force-sensing resistor** or simply an **FSR**) has a variable resistance as a function of applied pressure. |

| These devices are fabricated with elastic material in four layers, consisting of: | These devices are fabricated with elastic material in four layers, consisting of: | ||

| Line 14: | Line 14: | ||

| When external force is applied to the sensor, the resistive element is deformed against the substrate. | When external force is applied to the sensor, the resistive element is deformed against the substrate. | ||

| + | |||

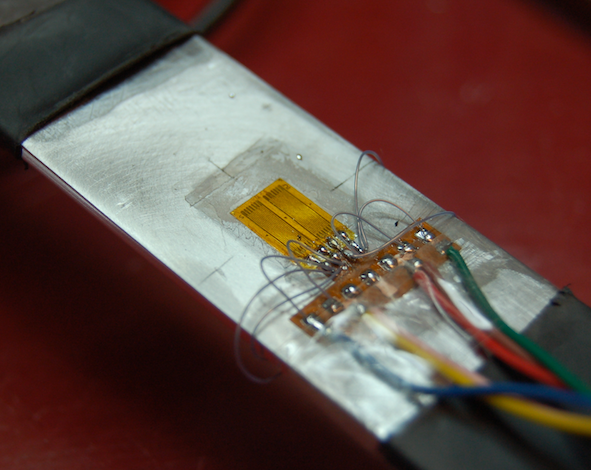

| + | There are several options for creating custom FSR shapes and configurations using pressure-resistive conductive materials such as conductive rubber, paper, and ink, or [[https:// | ||

| + | |Velostat]]. These flexible materials can be cut, shaped and stacked to better fit designs and resistance characteristics needed in a design. The pressure-resistive materials alone don't operate as sensors though, and must be configured with conductors to extract resistance changes from the material. | ||

| + | |||

| + | {{: | ||

| + | |||

| + | Utilizing the same voltage divider concept in commercial FSRs, both configurations should attach an additional fixed resistor in series with the sensor to avoid short circuits. The sandwich configuration shown above can also be extended to detect touch position by separating the bottom conductor into different shapes. With each conductive piece receiving its own voltage difference, relative touch position can be determined. | ||

| Operationally, | Operationally, | ||

| Line 19: | Line 26: | ||

| The same applied force will result in a wider output swing in a FSR than a strain gauge. Strain gauges, however, have higher accuracy than an FSR. Depending upon the particular needs of the application, | The same applied force will result in a wider output swing in a FSR than a strain gauge. Strain gauges, however, have higher accuracy than an FSR. Depending upon the particular needs of the application, | ||

| ==== Using an FSR ==== | ==== Using an FSR ==== | ||

| - | One of the most common circuits implemented to utilize an FSR's output is the [[tutorials: | + | One of the most common circuits implemented to utilize an FSR's output is the [[tutorials: |

| === Mounting === | === Mounting === | ||

| Line 105: | Line 112: | ||

| Resources: | Resources: | ||

| Notes:The information on the website of the company are very vague about the technical characteristics of the sensors. No datasheet is available. \\ | Notes:The information on the website of the company are very vague about the technical characteristics of the sensors. No datasheet is available. \\ | ||

| + | Variants:\\ | ||

| + | </ | ||

| + | |||

| + | <box 100% round blue|**Velostat**> | ||

| + | <box 30% round red right|Sources> | ||

| + | * [[https:// | ||

| + | </ | ||

| + | Description: | ||

| + | Datasheet: N/A \\ | ||

| + | Resources: | ||

| + | Notes: Material also known as Linqstat.\\ | ||

| Variants:\\ | Variants:\\ | ||

| </ | </ | ||

| Line 120: | Line 138: | ||

| * G. Burdea, //Force and Touch Feedback for Virtual Reality.// New York, NY: Wiley, 1996. | * G. Burdea, //Force and Touch Feedback for Virtual Reality.// New York, NY: Wiley, 1996. | ||

| * Interlink Electronics, | * Interlink Electronics, | ||

| + | * Koehly, Rodolphe, et al. " | ||

| * [[http:// | * [[http:// | ||

| {{tag> | {{tag> | ||