Table of Contents

How to Increase Reliability in Your Sensor Interfaces

This page is a log of reliability-related problems we have experienced in building and maintaining custom-made sensor-based interfaces for human-computer interaction. It includes details of problems along the entire chain, from sensors, to computer interfacing, to software processing. Some of these problems may not be easily resolved, but knowing what to expect can be half the solution.

Sensor failures

FSR breakage

In gluing FSR sensors to a pair of gloves on the tip of each finger, we have frequently found that they will tear in half. This often takes place at the boundary between the sensor and the soldered wire. Differentials in physical stiffness between the wire and the FSR material seem to cause mechanical stress at that boundary. Stretching, rotation, and bending through normal use eventually cause the FSR material to rip in half. We recommend that you find ways of attaching sensors such that the connection point does not experience any movement or stress during normal use. Applying hot glue to the connection boundary can avoid stress at the connection, but makes disassembly and connection debugging difficult after drying.

Interface failures

USB bus recognition

Several gestural interfaces have been created using the USB-HID analog-to-digital converter detailed on this site. While we do consider this a stable and reliable design, some instances of it have sometimes intermittently failed to be recognized by computer operating systems when plugged in. Sometimes it is the case that it does not show up in the Mac OS X System Profiler, but unplugging and replugging it, or plugging it into a different USB port causes it to eventually show up.

This intermittent behaviour has been traced to several causes. Occasionally unreliable connections have been found on the circuit board. Other times we have found that the problem stems from reliance on on USB bus power.

For example, some interfaces will not work when plugged into the USB hub available through a keyboard, but that the device works fine when plugged directly into the computer. We believe this is because the bus power is not available through the keyboard USB interface.

Other times devices which draw too much current from the USB bus may cause the USB port to shut down, or in extreme cases cause a reboot of the computer. Most passive sensing devices, however, do not draw this much power, so if this occurs it would be best to check for short circuits.

For devices which do draw a decent amount of current over USB, it is recommended to try using a powered USB hub. If the device works more reliably on a USB hub compared to being plugged directly into the computer, it may be time to think about incorporating an alternative power source, such as a battery pack, into the device.

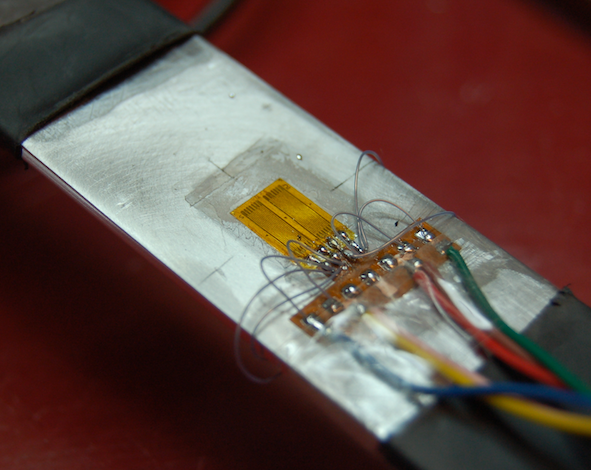

Connectors

It is important to ensure that your connectors are reliable. Problems that can occur include:

- bent pins

- unkeyed connectors resulting in mistakenly connecting things backwards

- unsecured connectors pulling out, or pulling half-way out

One technique for increasing reliability is to separate functional dependence on these connections – for example, if a connector is pulled out, does the device need to be rebooted, or will it continue working when you plug it back in? However, using secure connectors is extremely important for gestural controllers in particular, since live interaction techniques will often put stress on cabling.

We have had problems in the past with DB-9 connectors that did not use screws to hold them in place. Although pulling on them made it seem that they were fast, a brief movement with the device could cause it to pull out at a diagonal angle, causing some of the pins to lose connection.

To ensure that a controller which had several parts is always connected consistently, consider using different connectors for each connection, or at least keying the connectors if they are the same. This process involves cutting an unused pin from the mail end of a connector, and filling the opposite connector with glue. This ensures that no other connector of the same design will fit into the socket.

The alternative is to simply label all your connections well. This is still important, of course, but keying ensures that no erroneous connections can be made. While control-level signals usually do not cause problems, power connections may damage your circuits if improperly connected.

Software difficulties

- Avoid erasing objects in DIMPLE when changing demos. Quit the program and launch it back to avoid possible crashes.